Introduction to Hinged Concrete Frames

Hinged concrete frames have revolutionized the construction industry, offering innovative solutions for various structural applications. These frames provide a flexible and efficient alternative to traditional rigid designs, allowing for dynamic movement and enhanced structural integrity. In this blog post, we will delve into the world of hinged concrete frames, exploring their benefits, design considerations, and step-by-step guide to creating the ultimate hinged concrete frame.

Benefits of Hinged Concrete Frames

Hinged concrete frames offer a multitude of advantages over conventional rigid frames. Firstly, they provide exceptional flexibility, accommodating natural movements and deformations that occur during construction or due to environmental factors. This flexibility reduces the risk of structural damage and enhances the overall stability of the building.

Secondly, hinged concrete frames are highly adaptable, making them suitable for a wide range of architectural designs. They can accommodate complex geometries, curved structures, and unique shapes, providing architects with the freedom to explore creative and aesthetically pleasing designs.

Furthermore, these frames excel in seismic zones, as their ability to absorb and dissipate energy during earthquakes significantly reduces the potential for structural failure. This makes hinged concrete frames an ideal choice for regions prone to seismic activities.

Design Considerations for Hinged Concrete Frames

When designing a hinged concrete frame, several crucial factors must be taken into account to ensure optimal performance and safety. Here are some key considerations:

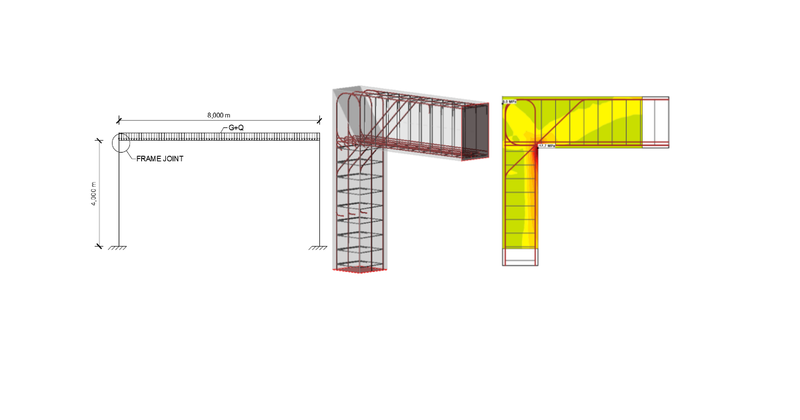

1. Structural Analysis

Conducting a thorough structural analysis is essential to determine the appropriate frame configuration, hinge locations, and material selection. This analysis considers factors such as load distribution, bending moments, and shear forces to ensure the frame can withstand the intended loads and meet the required safety standards.

2. Hinge Selection

Choosing the right type of hinge is critical for the success of a hinged concrete frame. There are various hinge options available, including steel hinges, flexible joints, and elastomeric bearings. Each type has its own advantages and limitations, so careful consideration should be given based on the specific requirements of the project.

3. Material Selection

The choice of concrete mix and reinforcement materials plays a vital role in the performance of hinged concrete frames. High-strength concrete with excellent durability and resistance to cracking is often preferred. Additionally, selecting the appropriate reinforcement, such as steel bars or fiber-reinforced polymers, ensures the frame can withstand tensile forces and maintain its integrity.

4. Construction Techniques

Implementing proper construction techniques is crucial to achieve a well-built hinged concrete frame. This includes accurate formwork construction, precise placement of reinforcement, and proper curing procedures. Ensuring that the hinges are installed correctly and aligned with the intended movement directions is also essential.

Step-by-Step Guide to Creating the Ultimate Hinged Concrete Frame

Follow these steps to design and construct an exceptional hinged concrete frame:

Step 1: Define Project Requirements

Begin by clearly defining the project requirements, including the intended use of the structure, load-bearing capacities, and any specific design constraints. This step ensures that the final design aligns with the project’s objectives.

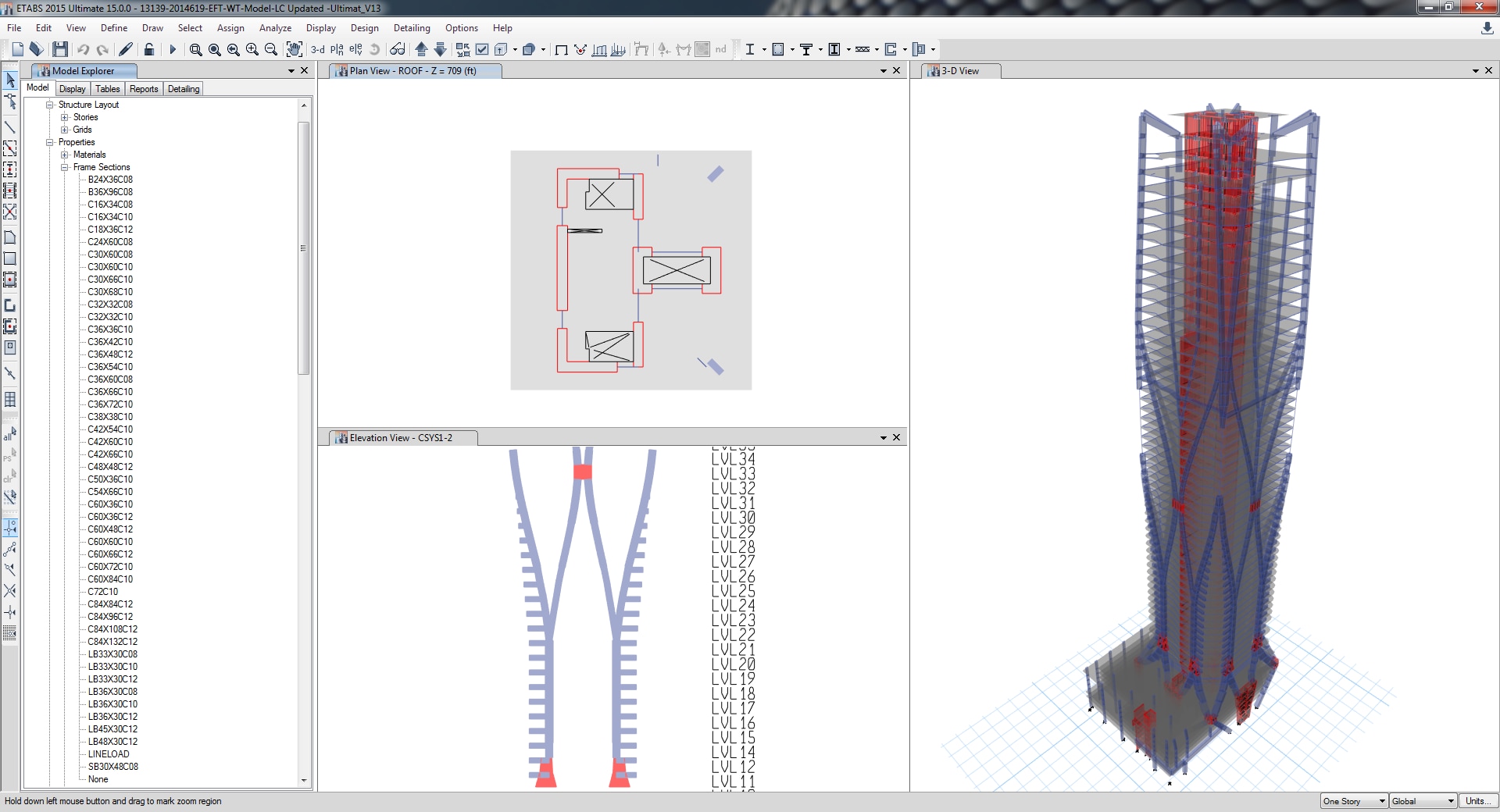

Step 2: Conduct Structural Analysis

Perform a detailed structural analysis to determine the optimal frame configuration, considering factors such as load distribution, bending moments, and shear forces. This analysis will guide the placement of hinges and the selection of appropriate materials.

Step 3: Select Hinge Type

Choose the most suitable hinge type based on the project requirements and structural analysis. Consider factors like load capacity, flexibility, and ease of installation. Consult with experts or refer to industry guidelines to make an informed decision.

Step 4: Determine Material Specifications

Specify the concrete mix design and reinforcement materials based on the structural analysis and project requirements. High-strength concrete with excellent durability and reinforcement capable of withstanding tensile forces should be prioritized.

Step 5: Create Detailed Drawings

Generate detailed drawings that illustrate the frame layout, hinge locations, and reinforcement details. These drawings serve as a guide for construction and ensure accurate execution of the design.

Step 6: Prepare Formwork

Construct the formwork with precision, ensuring it aligns with the designed frame layout. Pay attention to the hinge locations and make necessary adjustments to accommodate the hinges. Proper formwork construction is crucial for achieving the desired frame geometry.

Step 7: Place Reinforcement

Install the reinforcement materials as per the detailed drawings, ensuring proper alignment and spacing. Take extra care when placing reinforcement around the hinge areas to maintain the structural integrity of the frame.

Step 8: Pour Concrete

Pour the concrete mix into the formwork, following the specified mix design and curing procedures. Ensure that the concrete is placed and compacted uniformly to avoid any voids or weak spots. Proper curing is essential for achieving the desired strength and durability.

Step 9: Install Hinges

Carefully install the selected hinges at the predetermined locations. Ensure that the hinges are aligned with the intended movement directions and securely attached to the concrete frame. Proper installation of hinges is critical for the overall performance of the frame.

Step 10: Cure and Inspect

Follow the recommended curing procedures to allow the concrete to reach its full strength and durability. Once cured, thoroughly inspect the frame for any defects or deviations from the design. Address any issues promptly to ensure the structural integrity of the frame.

Conclusion

Hinged concrete frames offer a versatile and innovative solution for various structural applications, providing flexibility, adaptability, and enhanced seismic resistance. By following the design considerations and step-by-step guide outlined in this blog post, you can create the ultimate hinged concrete frame, ensuring optimal performance and safety. Remember to consult with experts and refer to industry guidelines for specific project requirements.

What are the key benefits of hinged concrete frames over traditional rigid frames?

+Hinged concrete frames offer enhanced flexibility, adaptability, and seismic resistance. They accommodate natural movements, reducing the risk of structural damage and providing architects with creative design freedom.

How do I choose the right hinge type for my project?

+Consider factors such as load capacity, flexibility, and ease of installation. Consult with experts or refer to industry guidelines to select the most suitable hinge type based on your project’s specific requirements.

What are the key considerations when selecting concrete and reinforcement materials for hinged concrete frames?

+Choose high-strength concrete with excellent durability and reinforcement capable of withstanding tensile forces. The selection should be based on the structural analysis and project requirements to ensure optimal performance and safety.